Eastbourne, All Saints’ Church

Eastbourne, All Saints’ Church

Harrison & Harrison 1929: 3 manuals 39 stops. Reconstruction of the organ actions, converting them to electro-pneumatic operation. (To view specification, click HERE).

Completed June 2015

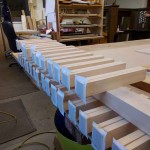

Soundboard, Actions and Chests

Re-construct Pedal Ophicleide and Great Tromba chests and actions with lever magnet primary and power motors. Repair chest.

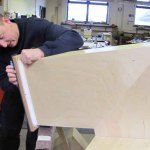

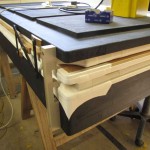

Tromba chest |  Tromba chest ready for working on |  Tromba chest | |

21st April 2015

Plugging holes in Tromba |  Sanding Ophicleide chest |  sanding | |

cleaning pallets |  new motors | | |

28th April 2015

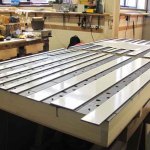

Ophicleide chest |  Ophicleide chest |  Ophicleide chest | |

leather for motors |  leathering Ophicleide motors |  leathering Ophicleide motors | |

leathering motors |  finished motors |  Ophicleide new motors | |

cleaned pallets |  gluing felt on pallets |  gluing felt and leather on pallets | |

gluing felt on pallets |  trimmed up pallets |  Tromba. New motors | |

05th May 2015

leathering Ophicleide chest |  leathering Ophicleide chest |  leathering Ophicleide chest | |

fitting Ophicleide power motors |  fitting Ophicleide power motors | | |

12th May 2015

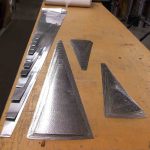

making Tromba valves |  Tromba valves |  Tromba pallets | |

Tromba pallets |  fitting Tromba pallets |  Ophicleide chest | |

9th May 2015

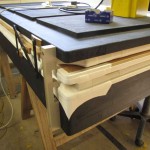

fitting out Tromba chest |  fitting out Tromba chest |  Ophicleide chest | |

Ophicleide chest | | | |

Pipework

Dust out the reed pipes and check tongues and wedges. Check the speech of the Tromba and Ophicleide.

Ophicleide pipes |  Ophicleide pipes |  Ophicleide | |

Ophicleide from above |  Tromba from above | | |

Work being finished onsite

pipework |  pipework |  pipework | |

Andy Scott, Head Voicer working |  Eastbourne pipework |  the team (left to right): Andrew Scott (Head Voicer), Craig Watson, Michael Clough (Team Leader) and Jaroslav Strazovsky | |

Ely Cathedral

Ely Cathedral

Harrison & Harrison 1908, 1975, 2000: 4 manuals 83 stops.

Changes to piston and stepper. Keyboards overhauled. Re-leathering of some internal and external reservoir gussets.

Pre-work

old toe piston positions |  old toe piston positions |  old toe piston positions | |

Console

A new stepper foot piston has been installed on an extended pattress in place of the Pedal reed 16ft foot piston. The Pedal reed 16ft piston has been relocated with its pattress to the left of the Swell to Great reversible. Keyboards have been over hauled, and existing piston units have had adjustment buttons replaced.

February 2015

new stepper added to thumb pistons |  new stepper added to thumb pistons |  new stepper added to thumb pistons | |

new stepper added to thumb pistons |  new keys and thumb pistons |  new stepper added to thumb pistons | |

new stepper added to thumb pistons | | | |

March 2015

new stepper added to thumb pistons |  new keys and thumb pistons |  new stepper added to thumb pistons | |

completed keys and pistons |  completed keys and pistons |  recovered swell pedals | |

new toe piston positions |  new toe piston positions |  new toe piston positions | |

Wind System

February 2015

Reservoir gussets have been re-leathered.

re-leathering external gussets |  re-leathering external gussets |  new internal gussets | |

March 2015

new external gussets |  new external gussets | | |

The organ (after work)

Exeter Cathedral

H&H 1933, 1965, 2003, based on earlier work by Father Willis, 1891. The main organ was dismantled in January 2013. It has been completely reconstructed, with a new layout within the famous Loosemore case, and new soundboards replace those of 1891. The original tonal scheme has been retained. The intention was to achieve a better distribution of sound, together with improved access for tuning and maintenance. 4 manuals, 70 stops. Click HERE to view the new specification

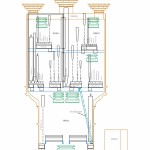

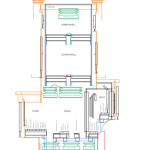

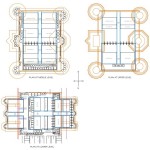

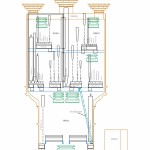

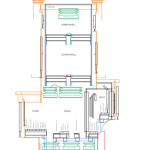

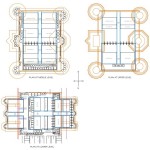

Design

The organ (pre-work) |  East section |  South elevation |  Plans |

Swell & Solo

New swell-boxes and shutter fronts were constructed for the Swell and Solo Organs

The Swell | | |

| | | |

Work done

The pipework has been re-arranged so as to give a more logical layout and eliminate those anomalies which have occurred in the course of various changes over the years.

Swell box construction |  Swell box construction |  Solo box open shutters |

Solo box frame | | |

Workshop Assembly photos

inside Solo box |  Lower Swell |  fitting up – the west side |

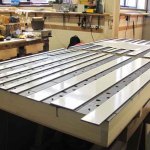

Soundboards, Actions & Chests

The electro-pneumatic key actions dated from 1933 and were of excellent quality, but because of the new layout and reconfiguration of the soundboards, most actions had to be renewed, and retain the identical three stage design.

New soundboards were also constructed. The new drawstop slider mechanism is electric.

inside Swell Reeds soundboard |  lower Swell stop action | |

upper Great soundboard |  lower Great soundboard |  soundboard & pipework |

Work done

<

inside the action |  inside Swell Reeds soundboard and action | |

Upper Great soundboard and action |  Lower Great soundboard | |

constructing lower Swell four stop soundboard |  lower Swell basses | |

| | | |

Solo Tuba soundboard | | |

| | |

le=”text-align: center;”>

Lower Great |  soundboards |  Upper Great soundboards |

assembly |  assembly of soundboards |  soundboards |

Pipework

All pipework was cleaned; stoppers were refitted, damaged reed resonators repaired & strengthened, and any necessary repairs were carried out.

pipework to be cleaned |  Great Trumpet |  Pipework |

Work done

Pedal pipework |  Pedal Trombone shallots & tongues | |

repairing the Great Trumpet |  repairing Great Trumpet |  Great Trumpet 8ft |

Workshop Assembly

Pedal pipework |  Pedal Trombone |  pipes |

Great Trumpet 8ft |  Great Double Trumpet |  Lower Swell Basses |

Wind System

Most reservoirs have been renewed, but the same traditional principles have been retained. There are now five double-rise reservoirs and five single-rise due to the space. New wind trunking was provided through out.

Pre-work

reservoir and conveyancing |  old conveyancing | |

Work done

Pedal Violone 32ft reservoir |  Pedal Violone 32ft reservoir | |

soldering conveyancing |  conveyancing |  16ft Open Wood |

trunking |  trunking |  trunking |

Workshop Assembly

reservoirs |  Great conveyancing |  reservoir being assembled |

Solo reservoir |  Tuba reservoir |  Upper Swell reservoir |

Upper Great reservoir |  assembly | |

Framework Assembly

In March 2014 the organ was assembled in the workshop as a trial run before going on site to the Cathedral.

Exterior Assembly photos

3rd March |  19th March |  27th March |  3rd April |

10th April |  17th April – fitting up the west side |  8th May |  8th May |

14th May |  21st May |  28th May | |

On Site

Photos taken on site at Exeter Cathedral

On site photos

Upper Great flapper |  Upper Great wind system |  Upper Great wind system and shutter mechanism |

Pedal flue |  Pedal Open Diapason chest |  upper access |

Solo shutters |  Solo Tuba and Upper Great |  Solo pipework |

Minstrel Gallery |  Tuba concussion |  Upper Swell |

Choir |  Double Open Diapason |  Lower Great |

Inside the organ on site at Exeter – underneath the reservoirs |  Nigel working inside the organ |  Jim Reeves Team Leader |

new panelling |  new position of the Open |  new 32ft toe piston |

manuals |  Swell and Great wind system being installed |  Pedal 32ft reed |

The team (top left to right) Kelvin Kent, Nigel Turner, Lee Berriman. (Middle left to right) Neil Davidson, Rob Newton. (Front) Jim Reeves |  Exeter, west side |  Exeter, on-screen side |

The organ after work (on screen) |  The organ after work (west) |  The organ after work (side view) |

Stephen Alliss (Tuner) & Andrew Scott (Head Voicer) |  Andrew Scott (Head Voicer) & Stephen Alliss (Tuner) |  Stephen Alliss (Tuner) | |

Hakadal Kirke, Norway (old organ, pre-work)

Hakadal Kirke, Norway

New organ, 2 manuals 17 stops, tracker action.

Below are a series of images showing the progression of work from old to new.

Click here to view the specification

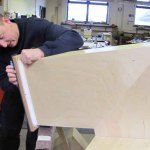

Soundboards, Actions and Chests

The soundboards will be made to our own well-proved design. Key actions will be tracker throughout.

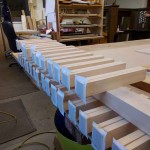

Great Pedal soundboard grid |

soundboard grids |

Great soundboard |

|

components ready for assembly |

Action fittings |

Action fittings |

|

soundboard grids |

|

|

|

1st – 24th October, 2014

Swell soundboard |

Great soundboard |

Great soundboard |

|

Great soundboard |

Swell pallets (cutting leather) |

Swell & Pedal soundboards |

|

rollerboard |

rollerboard |

sprayed rollerboard |

|

trackers |

Swell soundboard |

Swell soundboard |

|

27th October 2014

pallets |

|

|

|

|

|

|

|

December 2014

flooding the soundboard |

glue set in the Great soundboard |

cleaning Swell chest |

|

cleaning Swell chest |

|

|

|

|

|

|

|

05 – 19 January 2015

rollerboard |

rollerboard |

Great and Pedal trackers |

|

Great rollerboard |

Great rollerboard connected to the console |

Pulldown view of pallets |

|

assistor motors |

Key action |

key action |

|

action |

square beams connected to the chest |

Great Pedal square beams connected to the chest |

|

action |

square beams connected to the chest |

action |

|

Key springs |

Stop action unit |

stop action fitted below the chest |

|

26 January 2015

drawstop action |

drawstop action |

|

02 – 10 February 2015

key and stop actions |

key and stop actions |

key action |

key action |

stop action |

stop action |

Swell stop action |

Swell stop action |

a view of inside the organ |

|

30 Mar 2015

soundboards |

key action components |

key action components |

|

Console

The manual keys will have bone naturals and ebony sharps; the pedals will be faced in birch. Drawstops will be of rosewood with engraved inserts of alternative ivory.

Pre-work

pedals |

|

|

|

October 2014

Pedalboard |

Pedalboard |

Pedals |

|

November 2014

Fitting pedals |

Pedalboard |

Completed pedalboard |

|

Completed pedalboard |

Console coupler chassis |

Console coupler chassis |

|

December 2014

manual |

pedalboard |

back of the console |

back of the console |

console |

back of console |

inside console |

plumb bob & Pedal squares |

spraying stop action trondell |

|

stop action trondels |

stop action components |

spraying stop action trondell |

|

Pedal and manual trackers |

console chassis |

console chassis |

|

console chassis with pedal squares |

Pedal square fixings |

manuals |

|

console |

Swell keys |

Swell keys |

drawstop action |

keys |

Great & Pedal coupler backfalls |

Console chassis before fitting in |

Swell octave coupler |

manuals |

|

console |

rollerboards |

|

|

|

|

|

|

26th Jan – 2nd Feb 2015

Console |

inside console |

console assembly |

|

inside the organ |

inside the organ |

stop knob |

|

stop knob |

|

|

|

10 Feb

>

Stops |

Stops |

Console |

|

looking inside |

|

|

|

Swell

A new swell box and shutters will be provided.

Feb- July 2014

Swell box |

Swell box framework |

building Swell box frame |

|

swell box with shutters |

swell box with shutters |

|

|

[August – September 2014

Swell box |

Swell box being assembled |

Swell box assembly |

|

|

|

|

|

Swell box |

shutters |

shutters (closed) |

|

Pipework

New pipework to be made of spotted metal, poplar and pine.

February – March 2014

sanding pipe blocks |

clamping wooden pipes |

wooden pipes |

wooden pipes waiting to be stained |

|

|

April – September 2014

Great Stopped Diapason |

Great stopped Diapason |

|

|

October 2014

Metal stamped and cut out ready to be formed |

Great Trumpet 8ft |

Great Trumpet 8ft |

Swell Gedackt 8ft pipes |

Trumpet 8ft |

Great Trumpet top notes |

1-11 November 2014

Racking in Great 8ft stopped Diapason |

Racking in Great 8ft stopped Diapason |

Racking in Great 8ft stopped Diapason |

|

setting the c’s for voicing |

racking in mixture and Flautino 2ft Swell |

Hakadal – setting the c’s for voicing |

|

18 November 2014

Looking down through reed pipe |

reeds |

reeds |

|

reeds |

reeds |

reeds |

|

|

|

|

|

Dec 2014

racking in Great Trumpet |

racking in Great Trumpet |

racking in Great Trumpet |

|

racking in Great Trumpet |

|

|

|

Jan 2015

Swell Contra Oboe |

Swell Contra Oboe |

Swell Contra Oboe |

|

Great Principal |

Swell 16ft Contra Oboe |

Swell 16ft Contra Oboe |

|

Swell 16ft Contra Oboe |

|

|

|

02 February 2015

Pipes ready to be painted |

wooden pipes ready for painting |

Pipework added to the organ |

10 February 2015

|

|

|

inside the organ |

front pipes |

pipe racks |

|

metal and wooden pipes |

wooden pipes painted |

pipework |

|

Wind System

A new double-rise reservoir, trunking, conveyancing and blower will be provided.

April – May 2014

reservoir |

reservoir |

|

|

June – July 2014

Trunking |

|

|

|

August – September 2014

Leathering reservoir |

reservoir |

|

|

|

|

|

|

October 2014

reservoir |

reservoir |

trunking |

|

reservoir |

|

|

|

December 2014

wind trunks |

|

|

|

January 2015

Swell trunks |

Swell wind trunk |

Swell wind trunk |

|

reservoirs |

|

|

|

02 – 10 February 2015

Pedal Bourdon 16ft conveyance |

Pedal Bourdon 16ft conveyance |

conveyancing and pipework |

|

|

|

|

|

|

|

|

|

30 Mar 2015

reservoir |

|

|

|

Miscellaneous

Includes assembly, casework, building frame and stools etc

October 2014

bench |

Organ bench |

case panels |

building frame |

framework |

framework |

[November 2014

casework |

organ casework |

Console casework |

front casework |

front casework |

casework |

Completed bench |

casework |

casework |

Building organ in workshop |

Console |

|

|

December 2014

Jaroslav next to the Hakadal casework |

new casework |

Building the case |

Assembling framework |

|

|

|

19 January 2015

|

|

|

Assembly |

Assembling the framework and casework |

assembling console |

|

26 January 2015

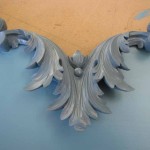

Casework decorations |

Casework decorations |

Casework decorations |

Casework decorations |

assembly |

|

|

|

|

|

|

02 February 2015

The organ with front pipes fitted |

front view of the organ |

Side view |

10 February 2015

Duncan Mathews, Production Director, testing out the Hakadal Kirke organ overlooked by Andrew Scott, Head Voicer (left) and Jaroslav Strazovsky, Team Leader (right). |

Duncan playing the organ |

Pipework added to the organ |

casework |

casework and console |

Working on the organ |

|

Working on the organ |

casework and front pipes |

|

|

30 Mar 2015

|

|

|

Carvings prepared for painting |

panels prepared for painting |

Carvings prepared for painting |

|

panels prepared for painting |

|

|

|

06 Apr 2015

Panels being painted |

Cut-outs being painted |

panels being painted |

painted panels |

decorative panel |

decorative panel |

|

Week Commencing 20th April 2015

Hakadal Kirke, Norway |

The team arrive at Hakadal Kirke, Norway |

The team ready to unload the container into the church |

|

inside the container |

Organ components unloaded ready to be unwrapped. |

Organ components |

Some of the framework ready to unwrap |

unpacking begins |

ready for unpacking |

|

The team: left to right, David Parsons, Ian Gibson, Jaroslav Strazovsky (Team Leader) and Lee Berriman |

|

|

|

Week Commencing 27th April 2015

Assembling the framework |

reservoir in place |

erecting framework |

|

soundboard in place |

reservoirs in place |

soundboards and reservoirs in place |

|

swell box being assembled |

assembly |

Unwrapping pipework |

|

more components unwrapped |

Lifting console up on to gallery |

Manoeuvring console in to place |

Week Commencing 4th May 2015

assembly of the console |

console assembly |

Casework |

Casework |

Looking up at the organ casework |

|

|

Week Commencing 18th May 2015

Our Head Voicer, Andrew Scott, reports that the voicing is going well and that the organ was used for a big celebration on Sunday 17th May where the organ gave a good account of itself.

close up of some stop knobs |

the completed organ |

view from below of the completed organ |

side view of the completed organ |

front view of the completed organ |

|

|

Jesmond, Holy Name of Jesus Christ RC Church

Jesmond, Holy Name of Jesus Christ RC Church

2 manuals 21 stops. Overhaul and install electric stop action

Actions and soundboards

Actions will be overhauled and restored and new magnets will be fitted. Solenoids will be fitted in place of the present drawstop action. Soundboards to be checked.

19th January 2015

leathering motors |  leathered motors waiting to be trimmed |  Great bottom board | |

26th January 2015

finishing off motors | | | |

| | | | |

10th February 2015

Pedal Bourdon action |  Pedal Bourdon action |  Pedal Bourdon action | |

Console

Keyboard overhauled and new contacts to be fitted. New Set & Cancel pistons to be installed. Pedalboard will be overhauled and refaced, and fitted with new contacts. Stop-tab units will be renewed and the console woodwork will be refurbished. Electronic coupling and piston systems will be installed in the console.

19th January 2015

working on the pedalboard |  pedalboard overhaul |  new pedal accidentals in beech | |

26th January 2015

Pedals finished with Teak Oil |  Finishing pedals |  Pedals placed on racks to dry | |

Pedals with new accidentals | | | |

10th February 2015

console |  pedalboard |  console | |

back of console |  electrics |  keys | |

Electrical System

Electronic coupling and piston systems will be installed in the console. New low-voltage cabling will be installed throughout the organ. An electric shutter engine will be installed to operate the swell shutters